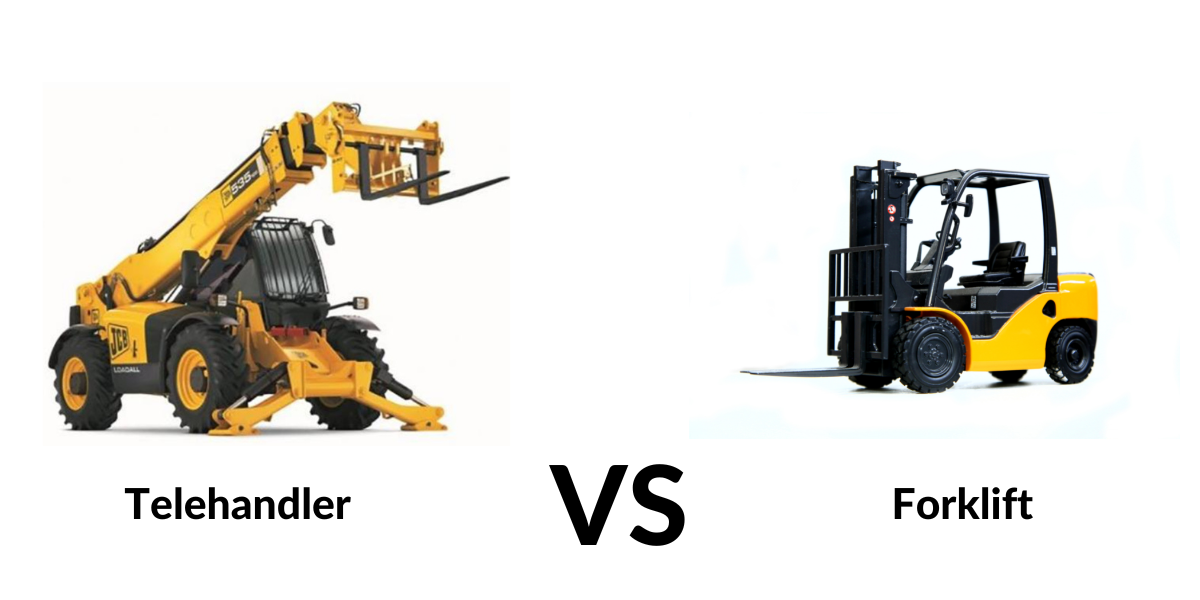

What’s the difference between a forklift and a telehandler (aka telescopic forklift)?

When working in the construction industry, you’re likely to use a combination of machinery and equipment to help lift, carry and move heavy loads, which needs to be done quickly, efficiently and safely.

We are often asked what’s the difference between a telehandler (telescopic handler) and a forklift and which piece of kit should we be hiring? The reality is that a telehandler and a forklift are two very different pieces of machinery and knowing the differences are important 😊. So here’s a quick rundown on the differences of using one machine over the other.

You need to use the machine outside and on rough terrain

Whilst you can hire a large forklift with pneumatic tyres to be used outside, if the terrain is rough or the ground is uneven, a telehandler is a better choice.

Because telehandlers have a three-sided footprint, they have better stability than a conventional forklift, particularly when it comes to working on uneven terrain. Because of the telehandler’s superior stability, it is suited to working outdoors and on construction sites where the ground may be slippery or uneven. Some models have hydraulic systems or outriggers for added stability, which can really help if you’re operating the telehandler on a slope.

The forklift is best suited to working in indoor settings like factories and warehouses where the ground is smooth and flat.

You’re limited on space

Forklifts are smaller and more compact than telehandlers, making them ideal for lifting and moving loads indoors where space is limited. Forklifts are often used in warehouse and factory settings where they may need to manoeuvre down narrow aisles and for loading and off-loading materials from trucks.

Telehandlers require more space and are best suited to outdoor locations. Telehandlers are also capable of moving loads without moving their base by simply extending their boom forwards, backwards, or side to side, while the forklift would have to drive backwards and forwards.

You need reach & manoeuvrability

Forklifts typically only lift loads vertically while a telehandler can be used to lift loads forwards, backwards and side to side. While both telehandlers and forklifts can lift and move objects, telehandlers are considered more versatile because they can do so without having to move anything other than their boom.

Telehandlers typically have a much bigger reach than conventional forklifts. However, depending on its size, a telehandler can reach up to 17m or more. Whereas forklifts, can generally only lift a load a few metres. A telehandler, because it has a boom can lift at an angle, in a way, a telehandler is similar to a crane.

Attachments

Both a forklift and a telehandler can be equipped with attachments making them both substitutes for backhoe loaders and tractor loaders, helping to move soil, gravel and rubble. There are different attachments available for forklifts, but the variety is limited. The telehandler is a more flexible piece of equipment where attachments can be fitted to the boom including pallet forks, hooks, scoops, and buckets, allowing it to lift a greater variety of loads.

Common uses of a telehandler are:

• Moving earth, rubble & building rubbish

• Lifting & moving building materials around site

• Giving construction workers access to elevated areas (when fitted with a platform)

• Cleaning up building sites

• Waste transportation

• Outside on rough and rugged terrain

Common uses of a forklift are:

• Loading and unloading materials from trucks

• Transporting materials from one location to another

• Manoeuvring down narrow aisles in warehouses

• Inside on flat ground

So next time when you’re wondering whether you should hire a telehandler or a forklift, give us a call and have us recommend you the right bit of kit to hire from GW Tool & Plant Hire from a day to a week, to a few weeks, to months even a year if need be!

Remember we will deliver all types of machinery or tools across Hampshire, Surrey and Berkshire.